Standardization increases quality in electrical design and enclosure construction

To provide customers with complete solutions of the highest quality, EAS has standardized its electrical engineering processes over the past years.

EAS Schaltanlagen GmbH in Grünfeld is known as a specialist for designing the automation engineering of complex machines and systems. To provide customers with complete solutions of the highest quality, EAS has standardized its electrical engineering processes over the past years. EPLAN's schematic generator has played an important part. When a company wants to be successful as an automation engineering service provider, it has to prove itself against tough competition: Time and costs as well as application-specific expertise play a role. EAS Schaltanlagen GmbH in Grünfeld near Würzburg has these prerequisites; the company has rapidly expanded in the past years. Whereas in 2004, EAS had 40 employees, it now has more than 100. In 2008, on company grounds, an extension for administration, development and production was put into operation. EAS Schaltanlagen GmbH is active in three business segments: automation, power engineering and preventive fire protection. The automation engineering division is a partner for mechanical and system engineering. Klaus Wohlleben, responsible for the automation engineering division: "We take on turn-key projects for our customers, from basic engineering, process control technology and enclosure production to commissioning - everything from one source." The power engineering division designs and produces low voltage switchgears (TSK) up to 5000A for industrial plants, computer centers and public buildings. The entire distributor spectrum is also covered. The product range also includes the manufacture of reactive power compensation plants that are also TSK-tested. Another business segment is structural preventive fire protection. Here, EAS is manufacturer of tested and approved fire protection enclosures, supplementary fire doors and fire-resistant partition wall systems, classified up to I/E/F90. With the development of the "SECURUS 90" security system with VDS approval, EAS has opened up further fields of activity. Extensive know-how for complex projects

Certainly another competitive advantage is the application technology know-how that EAS designers have acquired in numerous projects such as projects for process engineering, food engineering and the construction industry. Klaus Wohlleben: "We know the processes in our target branches - process engineering, transfer technology and special machinery production, and our goal, always, is to not 'only' be our customers' supplier, but to also use our process know-how to play an active role. Rarely is it a matter of standard machines; rather it is almost always a matter of individual projects whose schematics can contain up to 5000 pages. Important: The internal processes – and the CAD tools

Internal processes as well, i.e. engineering working methods, are certainly one of the differentiation criteria. Klaus Wohlleben "Our working method is our expertise." Here, at the latest, the tools come into play. When Ludwig Sinner, together with his partners, founded the company in 1990, he immediately implemented CAE software from EPLAN with which he by then had six years of experience. Now, four automation engineering designers and three power distribution engineers work with EPLAN. Growth calls for reorientation: Process standardization

In 2004, before a decision was made to migrate to EPLAN Electric P8, there already was a reorientation of CAD-supported electrical design. Ludwig Sinner: "Due to rapid growth, it made sense to restructure processes." Background: Up until this point in time, when a new project started, engineers first asked whether there was a similar project in the past. From these, components or parts were then used and varied as needed. Ludwig Sinner: "The success of this pragmatic method is highly dependent on the knowledge of the individual - and it is by no means straightforward. That's what we wanted to change." The right tool: The schematic generator

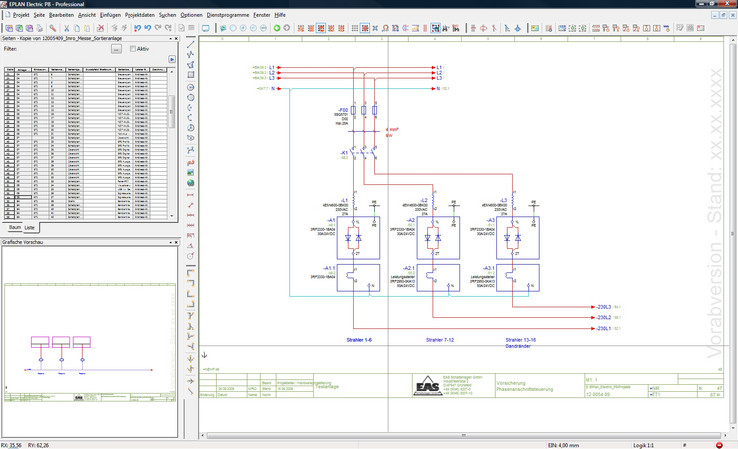

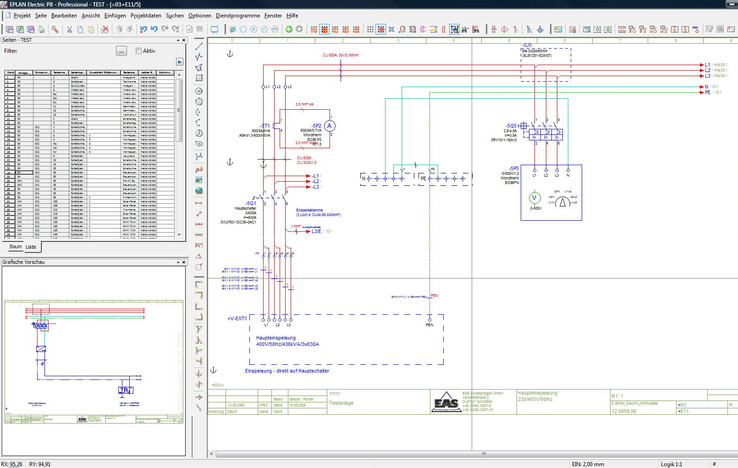

Therefore, Mario Rohde was given the task of restructuring the engineering processes within the company. During this period, EPLAN introduced a new version of the schematics generator which extensively supported designers when creating schematics. Ludwig Sinner: "We had already used this tool when it was still an integral part of EPLAN 5.60. With the EPLAN 5.70 release, the generator with extended functions became a separate product. We gave a lot of thought as to whether this investment 'computed' and the result was positive. Our goal was for the schematic generator to advance standardization." Interest in the new development led to EAS being a Beta tester for the schematic generator. Mario Rohde: "We made suggestions for improvement and found an attentive ear. We now use all of the generator's modules and benefit from a uniform quality standard for our schematics. In cooperation with our customers, production, and commissioning personnel, we have defined and implemented standards in the schematic generator." The result convinces both EAS and its customers: The standardized diagrams are of high quality. They have considerably fewer errors - and have a modular structure. In the case of change requests, EAS also stays flexible, because all characteristics and properties of a project can be variably described and controlled – for example, device tags, electrical characteristics, function text, part numbers and cable types. Customer survey shows: Standardization is the right way

A customer survey shows that this is the right way. Klaus Wohlleben: "We asked our customers what they like about our schematics and what can be improved. The answers were unanimously positive. Both the engineering service providers and the system engineers themselves are under a great deal of time pressure and therefore appreciate standardized schematics that have a uniformly high level of quality. However, Mario Rohde points out that such standardization is labor intensive and as such cannot be implemented overnight. "This goal can only be achieved in the medium or long term and we have adjusted the generator a lot to our requirements. But now we have a tool that can clearly improve the electrical design processes." New EPLAN platform: What is the system's potential?

Two year after EAS started with this standardization, solution provider EPLAN introduced the new platform. EAS looked closely into the software's possibilities. Ludwig Sinner: "We asked ourselves, what is the system's potential and quickly struck up a conversation with EPLAN and, just like with the generator, we made some suggestions that they also implemented." This includes, for example, that parts data is displayed when the designer clicks a part. This is helpful when selecting a part. EAS often uses the EPLAN Data Portal for this task. The selection of components and items facilitates work. Common fluid and electrical engineering basis

In the meantime, preparations for migration to EPLAN Electric P8 are complete and the first "real" projects are already being created using the new platform. Another advantage is quickly seen: For some months, EAS has been using EPLAN Fluid for fluid engineering and can now profit from a common fluid and electrical engineering data platform. This also saves repetitive work and synchronization effort and in the end increases the quality of the design. Integration continues - for the benefit of the customer

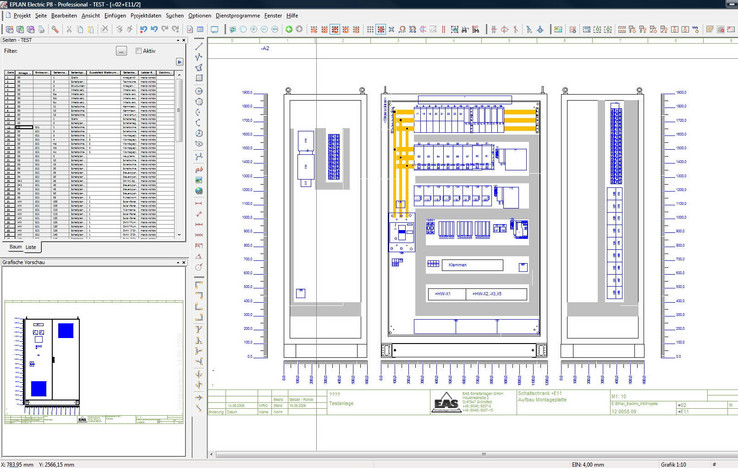

But it doesn't stop there – integration continues. A few months ago, EAS put a new CNC machine for sheet metal parts into operation and connected it directly to the EPLAN Platform in order to process sheet metal parts using computer aided manufacturing. In the course of setting up this connection, EAS looked into the future use of EPLAN Cabinet. Then, in the next step, for example, cables could also be prepared directly by CAM.

The actual design work takes place on the computer - but at project meetings, the plot helps Mario Rohde and Klaus Wohlleben (left to right) orient themselves.

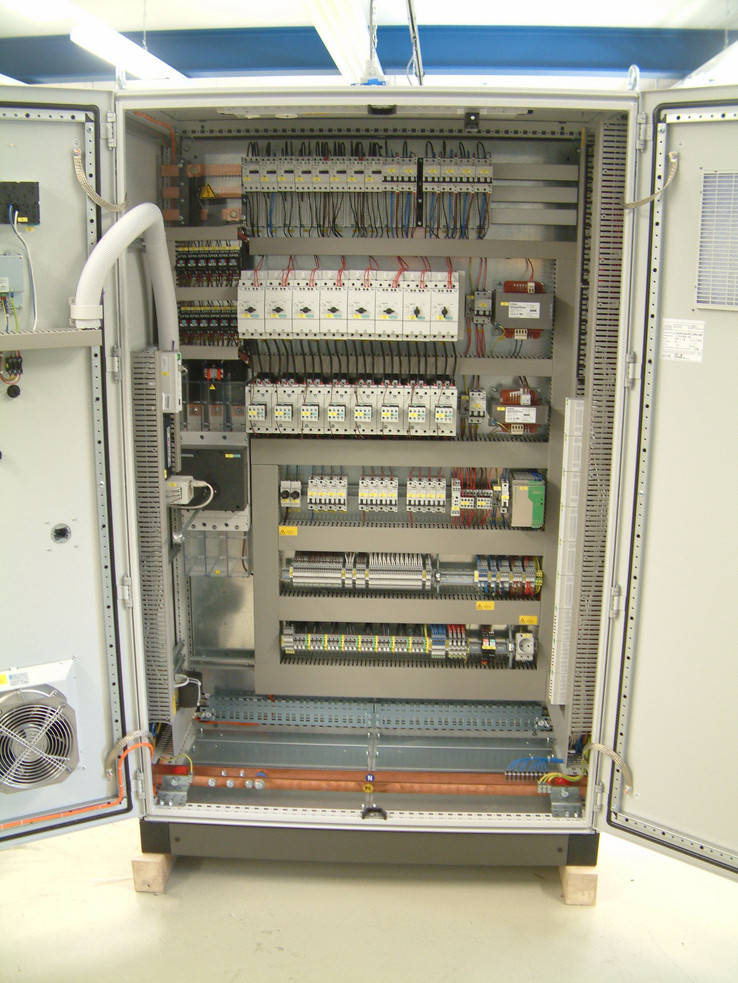

From basic engineering to enclosure production to commissioning - the entire enclosure construction process is supported.

Typical schematics in EPLAN Electric P8. Advantage: An integrated link to fluid engineering based on a consistent platform.